Yarn

Our yarn division facilitates the production of the finest combed cotton yarn. While 50% ofthe facility is dedicated to manufacturing. And we are exporting wide range of prime quality cotton yarns. These yarns are used for Knitting, Weaving, Yarn Dyeing and Processing.

In Sahana Exports, the production process begins right from the procurement of basic raw material such as cotton, cotton blended, viscose, modal, polyester which is both natural and artificial fibers in making a quality yarn. The fiber chosen must be lengthy, fineness, strength, rigid and mature to make yarn of finest quality.

Spinning

The unit is equipped with state-of-the-art machinery, producing variety yarns. All the yarn products are of high quality that meets the International market expectations. With a well-coordinated infrastructural set-up, we expertise in various specialty yarns.

Spinning is the twisting together of fibers to form yarn. Our spinning unit, Sahana Exports turns quality cotton into high grade yarn with state-of-the-art modern machineries. The superior quality raw cotton selected by our quality experts are mixed appropriately and processed with Cotton Contamination Cleaner machines to discard impurities.

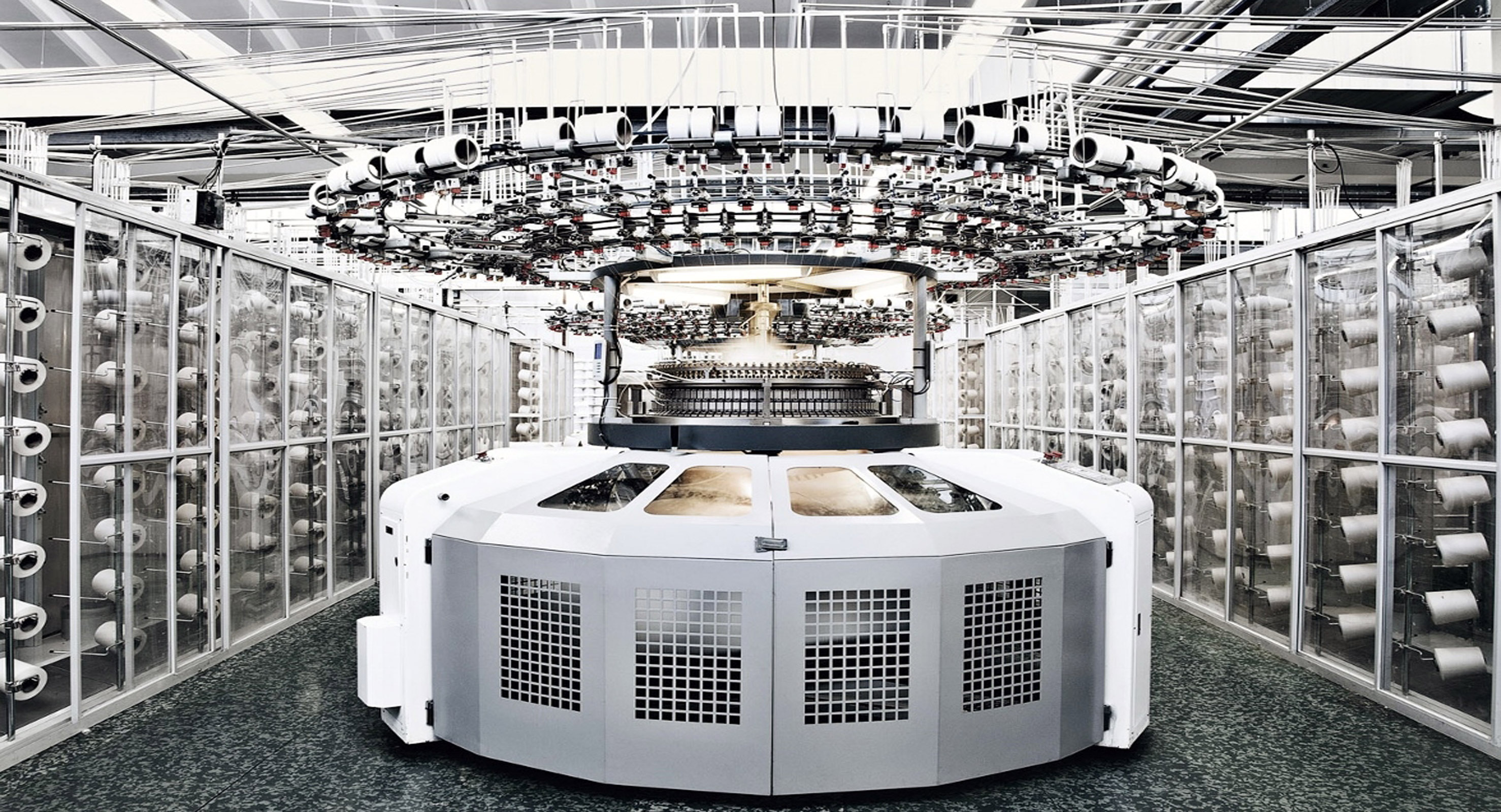

Knitting

The knitting unit is equipped with hi-tech machines capable of producing a wide variety of knit structures. A continuous programme of research and development ensures that the knitting unit has the capability required to meet the latest trends. Hence customers have access to a wide collection to choose from.

The result, quality and the nature of the product is determined based on the knitting machine, therefore we have invested the best knitting machines of renown make. We are highly capable of knitting fabrics within our efficient knitting unit with a delivery capacity of 6000kgs/day with our high tech machineries such as Single jersey auto stripper, Rib jacquard auto stripper and Rib & Interlock auto stripper.

Dyeing

Some of the finest and most modern dyeing machines from the most recognized brand at work. All our efforts go towards providing our customers with the kind of colors that they desire.very intensive experience, expertise and the most modern machinery to result perfection and achieving uniformity

Dyeing in textiles is a process in which color is transferred to a finished textile or textile material to add permanent and long-lasting color.Dyeing can generally be described as a colored substance that has an affinity to the substrate to which it is being applied. The dye is generally applied in an aqueous solution and may require a mordant to improve the fastness of the dye on the fiber.

Lab

To ensure height of quality, maintaining consistency of buyers requirement all along, We got the top-of-the-line laboratory having all testing facilities which conducts routine tests to maintain quality standards, and to guard against chemicals harmful for human body. It conducts several other customized tests as well.

In our in-house laboratory and quality control is done in 3 stages for color fastness, shrinkage, appearance after wash and pilling. Finished fabric, before going to production "(cutting& stitching)". Mid production cross checking. "Few garments taken randomly from the finished, packed garments"

Printing

Our advanced printing facilities ensure that the customer gets the brightest and the most accurate design & color, which are double-checked for colourfastness. The printing process does involve several stages in order to prepare the fabric and printing paste, and to fix the impression permanently on the fabric.

The four main methods of textile printing are block, roller, screen, and heat transfer printing. Printing is the process of applying color to fabric in definite patterns or designs. Printing also described as localized dyeing is used for applying colorants to the selected areas of the fabric to build up the desired design.

Embroidery

We have well equipped with Computerized multi Head Embroidery Machine with Advanced designing system and elaborate matching processes are employed to achieve intricate patterns and sophisticated illustration.

Embroidery section is one of the most important sections of apparel manufacturing industry. It is one of the special tasks which is done according to the buyer’s requirements. In the past embroidery had done by using the manual method. But now a day, it is done by applying computerized methods. In ready-made apparel sector, computerized embroidery machine helps to produce very complex design within a very short period of time.

Production

Factories are equipped with Automatic Production Handling systems to reduce manual handling, increase productivity and better tracking of production status. Production process is elaborate and engrossing where every team member involved plays an essential role.

Production of fabrics makes out our vast differences between the other market players. We prefer a qualitative product to our customer's and so our production process deals with the checking of all kinds of technicalities which the fabric has gone through in the manufacturing process.

Packing & Warehouse

It is the most important stage in product manufacturing, which cast a huge impact on the product sale. Now a days predominately one concept is We give much importance to finishing of a garment by using proper packing equipment.

After completing the entire manufacturing task, apparel is required to be packed. After packing, it is placed in cartons as per instructions and then it is stored in a storage section before it is delivered to the respective buyer. Packaging refers to the container that carries a product.

Logistics & Delivery

We provide the Delivery mode which is convinient to the customers. For shipments to most western countries including, but not limited to, the USA and EU, UK the garments have to be packed in boxes with one or more poly bags inside them, protecting the clothes.

Our many years of knowledge and our excellent customized service help to turn into a credulous and trustworthy partner for all tasks in the textile logistics area. Our documentation & logistics team takes care of complete shipping activities with updates of copy documents, schedules & tracking till the cargo is delivered to the customer's warehouse as committed. Thus maintaining a good track record of close follow up.